Hotmelt film adhesive has been used in many applications and industries. In the market, there are a lot of choices. Here we will explain to you how to choose the best film adhesive for your applications.

News and Insight

Our blog keeps you in touch with the latest innovations and trends.

What is a headliner?

Headliners are made of composite fabrics, a combination of different materials with different functionalities. The composite parts are adhered to the roof of the car and help to improve the interior appeal as well as provide an element of insulation against heat and noise.

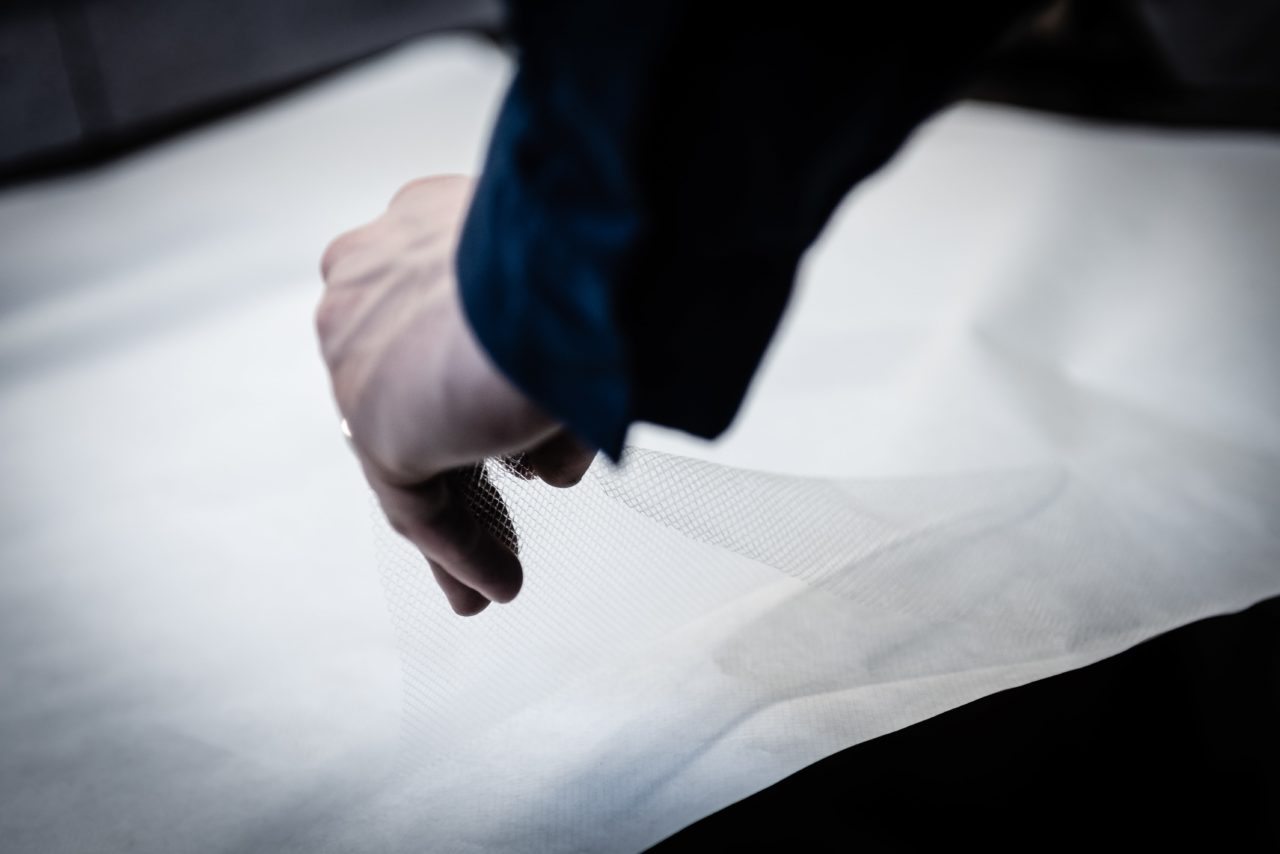

A typical headliner consists of multiple layers: a face side, a rigid core in the center, and a backing. The different layers consist of a multitude of materials such as knit or non-woven fabric, rigid foam, reinforcement material, etc. Liquid and dry adhesives (film, web, net) are then used to bond the different layers together in order to enhance the headliner’s unique shape and contours.

What is the function of headliner ?

The multi-layered headliners bring together various functionalities:

- better look and comfort through soft touch

- stiffness of the roof

- absorption of excess noise from the outside

- insulation against heat and cold, regulation of internal temperature

- improved acoustics for audio systems

Introduction

Hotmelt adhesive is also called thermoadhesive or thermoplastic adhesive. It can be manufactured and produced in different forms, such as granule, powder, stick, web, film, net on a roll.

Thermoplastic hot melt adhesive on a roll can combine various materials, like foam, textile, and leather, aluminum, which can be applied in automotive, garment, shoes, leather, and cosmetic and filtration applications with a clean lamination process.

Confection of sanitary masks (FFP1) using our hotmelt non-woven fabric.

We’ve developed our own hotmelt hybrid non-woven technology. Here are the different requirements

to produce your own FFP1 masks using our products.

Hotmelt adhesive web is also called thermoadhesive Web. It is used to bond and laminate with different materials, such as textile, leather, foam, 3D spacer, aluminum sheet. Its unique characters (soft, breathable, light weight) makes it the most versatile adhesive in various applications.

Hotmelt adheshive Web is made of 100% thermoplastic polymer resins. The final form is in roll with different width and weight. The fabric structure are like nonwoven. It can be activated with heat, like flatbed lamination machine, hot roller, hot press, heated air etc. For bonding process, it is more clean and easier to handle comparing to hotmelt powder.

41 Avenue Montaigne

68700 CERNAY – France